We provide all services from planning, development, construction and operation of system that a corporation needs. Especially, we develop and supply equipment to test various performance of power transmission devices such as engines and transmissions of automobiles. We also have the ability to build test equipment for power transmission devices that meet user's requirements.

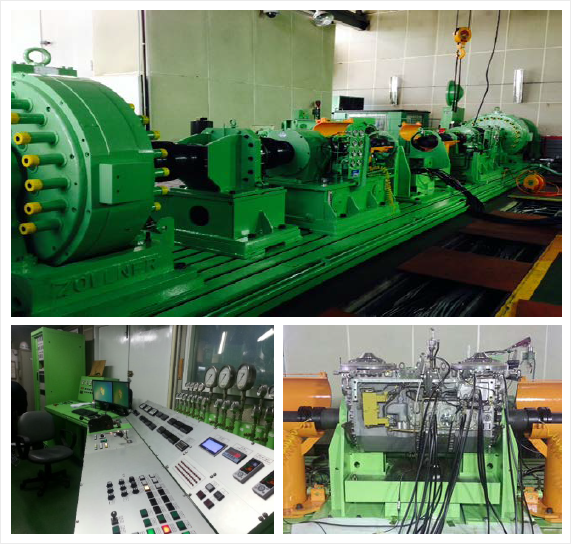

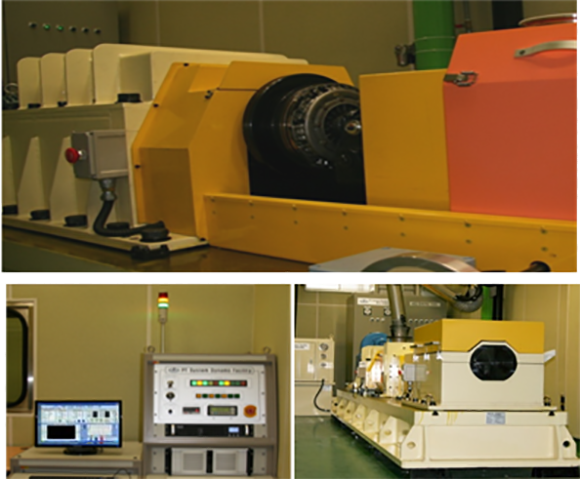

It is the equipment that tests performance and durability of transmission. Transmission plays a very important role in the automobile as a power transmission device and influences driving performance as well as fuel consumption according to performance. Therefore, the performance and durability of transmission must be measured using qualified equipment and a reliable transmission must be applied to a vehicle.

This test equipment conducts preliminary failure analysis for K9 transmission (Model: X1100-5A3) and final inspection specified in window maintenance work request after complete disassembly and repair, and judges status of automatic calibration pass or fail. It is specially designed and manufactured for the purpose of preliminary failure analysis.

| TEST EQUIPMENT NAME | TRANSMISSION (1,000@×1,100-5A3, K9) |

| TEST CONDITION | 34 ITEM TEST MODE FOR TRANSMISSION |

| INPUT POWER | ENGINE (MTU881 735Kw@3200RPM) |

| DYNAMOMETER | EDDY CURRENT DYNAMOMETER (1,000HP@3000RPM) |

| BRAKE CAPACITY | CALIPER DISK BRAKE(3,000Kgf-m) |

| ROOM SIZE | 22M×15M×12M |

| PROGRAM | DELPHI 7.0 |

| CUSTOMER | CONSOLIDATED MAINTENANCE DEPOT (2006, 2011) |

This test equipment conducts the preliminary and failure analysis for K1 transmission (model: LSG 3000) and final inspection specified in window maintenance work request after complete disassembly and repair, judges status of automatic calibration as pass or fail. It is specially designed and manufactured for the purpose of preliminary failure analysis.

| TEST EQUIPMENT NAME | TRANSMISSION (1,500@LSG 3,000, K1) |

| TEST CONDITION | 21 ITEM TEST MODE FOR TRANSMISSION |

| INPUT POWER | ENGINE (MTU 12V 369TC43 1,100Kw@1,900RPM) |

| DYNAMOMETER | EDDY CURRENT DYNAMOMETER (1,500HP@3,500RPM) |

| BRAKE CAPACITY | CALIPER DISK BRAKE(3,000Kgf-m) |

| ROOM SIZE | 22M×15M×12M |

| PROGRAM | DELPHI 2012 |

| CUSTOMER | CONSOLIDATED MAINTENANCE DEPOT (2015) |

This test equipment is for performance and durability test equipment for K9 transmission (Model: X1100-5A3), performs initial tests as specified by the acceptance test request for the transmission. It is dedicated test equipment designed and manufactured for performance analysis and to judge status of automatic calibration as pass or fail. .

| TEST EQUIPMENT NAME | TRANSMISSION (2,000HP@X1100-5A3, K9) UPGRADE |

| TEST CONDITION | 34 ITEM TEST MODE FOR TRANSMISSION |

| INPUT POWER | ENGINE(MTU881 735Kw@3,200RPM) |

| DYNAMOMETER | EDDY CURRENT DYNAMOMETER (2,000HP@3,000RPM) |

| BRAKE CAPACITY | CALIPER DISK BRAKE(3,000Kgf-m) |

| ROOM SIZE | 22M×15M×12M |

| PROGRAM | DELPHI 7.0 |

| CUSTOMER | S&T 중공업㈜ (2010) |

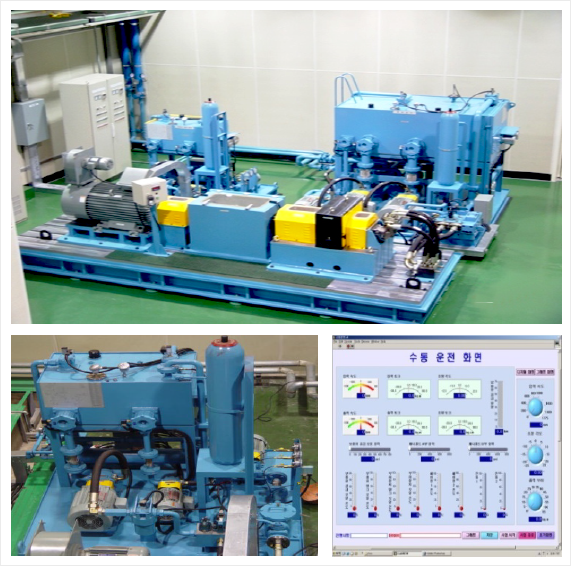

This test equipment is designed to conduct the final inspection, judge the status of quality as pass or fail, and assess the performance of transmission of hydraulic power steering as specified in the test acceptance request.

| TEST EQUIPMENT NAME | HYDRO-STEERING UNIT (240HP@X200-5K, K200) |

| TEST CONDITION | 10 ITEM TEST MODE HYDRO-STEERING UNIT |

| INPUT POWER | AC MOTER (400HP@3,000RPM) |

| DYNAMOMETER | HYDRO DYNAMOMETER (250HP@4,500RPM, 110cc/rev) |

| FLYWHEEL | Inertia 2kg-m, 4,000rpm |

| ROOM SIZE | 13M×9M×10M |

| PROGRAM | LABVIEW |

| CUSTOMER | CONSOLIDATED MAINTENANCE DEPOT(2015) |

This test equipment is used for the hydraulic cylinders for tank and armored vehicles to carry out the final inspection as specified in the test acceptance request, to determine the status of quality as pass or fail, and to assess the performance of a vehicle.

| TEST ITEM | SERVO CYLINDER, SERVO VALVE (MAX 450BAR, K9) |

| TEST CONDITION | 150 ITEM TEST MODE SERVO CYLIDER, SERVO VALVE |

| HYDRAULIC | PROPORTIONAL CONTROL(MAX. 70bar, 500L) |

| MEASUREMENT SENSOR | FLOW, PRESSURE, TEMPERATURE, LVDT |

| FLYWHEEL | Inertia 2kg-m, 4,000rpm |

| ROOM SIZE | 12M×5M×8M |

| PROGRAM | LABVIEW 2010 |

| CUSTOMER | CONSOLIDATED MAINTENANCE DEPOT(2015) |

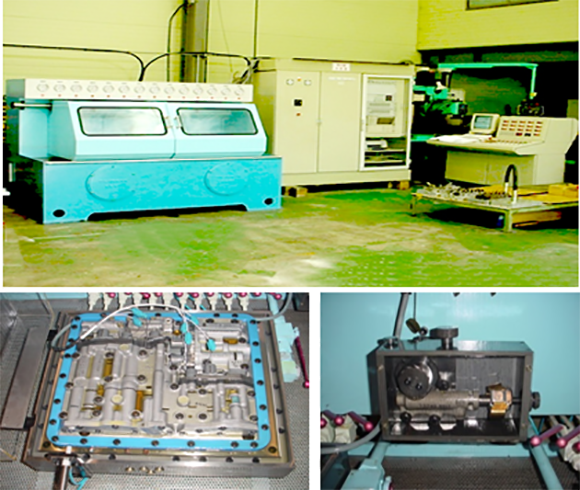

This test equipment is used to test valve body units for tanks and armored vehicles to carry out the final inspection as specified in the test acceptance request, to determine the status of quality as pass or fail, and to assess the performance of a vehicle.

| TEST ITEM | HYDRO VALVE, PUMP UNIT(K200, K77) |

| TEST CONDITION | 150 ITEM TEST MODE FOR HYDRO VALVE, PUMP UNIT |

| INPUT POWER | AC MOTOR (15KW@3500RPM) |

| MEASUREMENT SENSOR | FLOW, PRESSURE, TEMPERATURE, LVDT |

| ROOM SIZE | 9M×8M×10M |

| PROGRAM | LABVIEW 6.0 |

| CUSTOMER | CONSOLIDATED MAINTENANCE DEPOT(2003) |

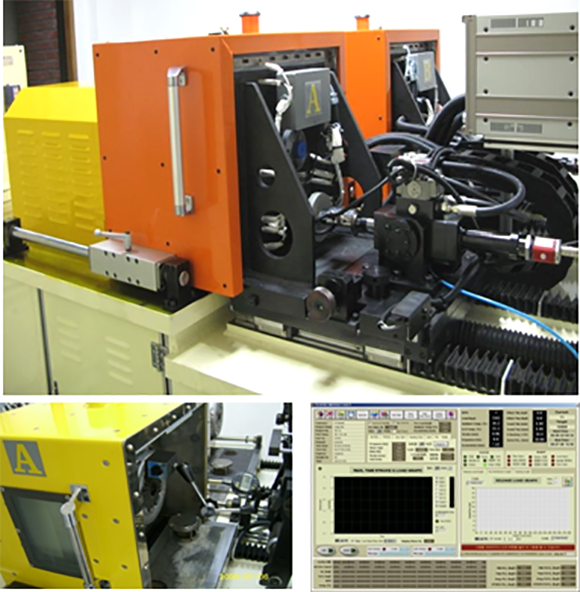

This is dedicated test equipment designed for acceptance of clutch overload, and to perform the final inspection as specified in the inspection request, to determine the status of quality as pass or fail, and to assess the performance of a vehicle.

| TEST ITEM | CLUTCH DISK ASS'Y (Φ160 ~ Φ300) |

| TEST CONDITION | 4 ITEM TEST MODE FOR CLUTCH |

| INPUT POWER | SPINDLE MOTOR (15.2KW@9,00RPM) |

| CLAMP LOAD | MIN 100 ~ MAX 600 kgf |

| STROKE | MAX 20mm |

| MEASUREMENT SENSOR | LINEAR, LVDT, LOAD CELL, RPM |

| ROOM SIZE | 5M×3M×3M |

| PROGRAM | LABVIEW 8.0 |

| CUSTOMER | PHC VALEO (2006, 2008, 2010) |

This is dedicated test equipment designed to accept clutch durability, carry out the final inspection as specified in the inspection request, to determine the status of quality as pass or fail, and to assess the performance of a vehicle.

| TEST ITEM | CLUTCH DISK ASS'Y (Φ160 ~ Φ300) |

| TEST CONDITION | 4 ITEM TEST MODE FOR CLUTCH |

| INPUT POWER | SPINDLE MOTOR (15.2KW@9,00RPM) |

| CLAMP LOAD | MIN 100 ~ MAX 600 kgf |

| STROKE | MAX 20mm |

| MEASUREMENT SENSOR | LINEAR, LVDT, LOAD CELL, RPM |

| ROOM SIZE | 5M×3M×3M |

| PROGRAM | LABVIEW 8.0 |

| CUSTOMER | PHC VALEO (2006, 2008, 2010) |