We provide all services from planning, development, construction and operation of system that a corporation needs. Especially, we develop and supply equipment to test various performance of power transmission devices such as engines and transmissions of automobiles. We also have the ability to build test equipment for power transmission devices that meet user's requirements.

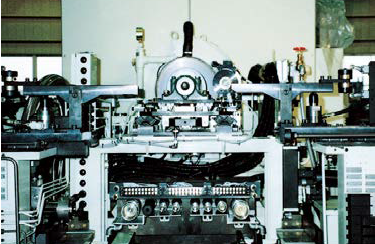

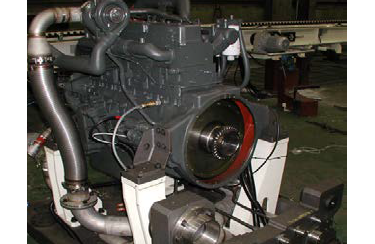

It is necessary to verify performance of manufactured engines and this equipment is a device that tests the engine quality by measuring the overall performance of the engine and examines whether a reliable engine is applied to the vehicle.

This is a test device that measures and analyzes torque, pressure, temperature, etc. by rotating the engine step by step without firing in the condition that the Intake & Exhaust Manifold is attached or detached to the engine long block.

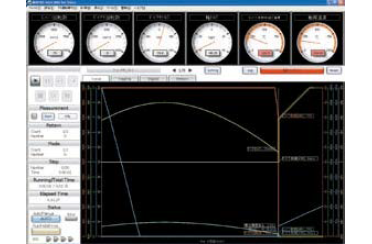

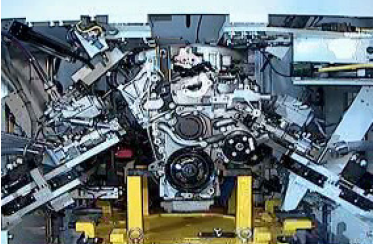

It measures, analyzes and records torque, revolutions, efficiency, fuel consumption, temperature and pressure in the field in real time by a measuring sensor mounted on the dynamo equipment which measures the mechanical face, speed and power of the motor, engine, transmission, etc. as test equipment which judges pass or fail of engine performance.

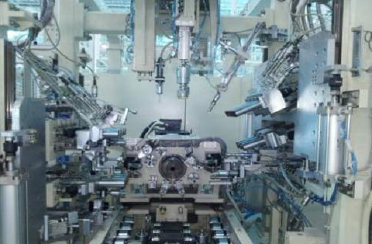

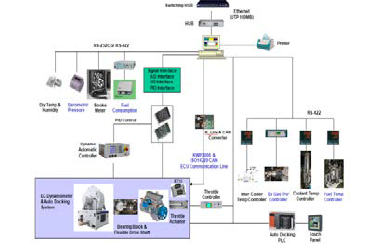

* This a facility that automatically transfers a high-horsepower engine such as an electronic and mechanical generator by using a dedicated cart and automatically measures the engine performance by building an Auto Docking & EOL System.

* It is the facility to automatically measure performance of an engine.

* Rigging part, unrigging part and engine buffer line RGV Conveyor System, etc. are all automatically built up.

This is a system to transport electronic and mechanical generators and mid-sized engines using dedicated carts, and to automatically measure engine performance by building an Auto Docking & EOL System. Rigging, unrigging parts, and the RGV Conveyor System are fully automated.

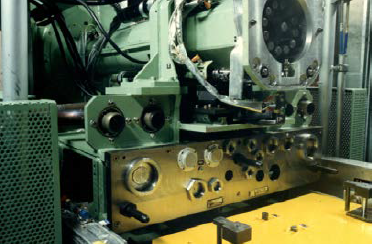

Engines for Electronic and mechanical generators are transported by dedicated trucks, and Semi Auto Docking & EOL System is installed to automatically measure engine performance.

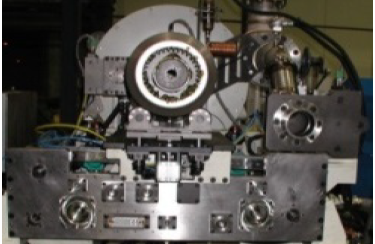

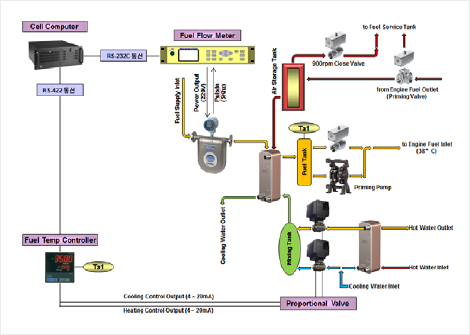

This equipment has priming and un-priming piping circuits with engine coolant temperature control devices.

Engine exhaust pressure regulators and circuits for measuring temperature, pressure, and smog are included.

It consists of an engine intercooler temperature controller, temperature and pressure measuring circuits, and adjusters for upper, lower, front and rear parts of an intercooler.

Equipment for engine, fuel, and temperature with circuits for measuring temperature and fuel consumption ratio

Automatic circuits for priming, un-priming, and extracting air are installed.

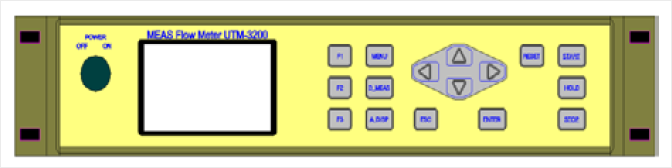

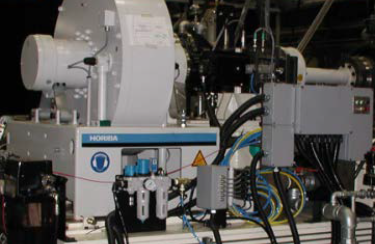

This is measurement equipment for measuring Mass Flow (continuous measurement type) which can measure fuel consumption to a higher degree.

| Model | TypeU (High performance model) |

TypeS (Single, straight-tube model) |

TypeB (Low-price, general-purpose model) |

|---|---|---|---|

| Nominal size | 1/4”, 10 to 150mm | 15, 25, 40, 50, 80mm | 15, 25, 40, 50 mm |

| Connection standard | JIS 10, 20, 30, 40, 63K ASMI/JPI 150, 300, 600 |

JIS 10, 20K ASME/JPI 150 |

JIS 10, 20, 30K ASME/JPI 150, 300 |

| Applicable fluids | Liquid, gas | Liquid | - |

| Flow range | 0 to 372000kg/h (12 types) | 0 to 108000kg/h (6 types) | 0 to 96000kg/h (6 types) |

| Operating temp. range | -200 to +200℃ | -40 to +130℃ | -40 to +125℃ |

| Maximum operating pressure | 9.4MPa *1 (differs by nominal size) | 2.45MPa | 7.9MPa |

| Accuracy (fluid flow) | ±0.1% of RD ±ZS *2 (differs by nominal size) |

±0.2% of RD±ZS *2 | ±0.2% of RD±ZS *2 |